Pitch

Current NZEB only depend on PV for electricity. One choice limits potentiality. Why not design heat engine to drive generator as 2nd choice?

Description

Summary

Indeed, photovoltaic is convenient for electricity, but average efficiency is only ~14% and thermal energy is simply discarded.

How about firstly convert solar energy to heat by flat plate or conic-curved mirror or lens solar collector, then convert heat to power by heat engine? In this way, there will exist double harvest: power, and rejected heat that can further be used inside building.

By current tech, the efficiency of first step can be up to 60%, and the rest of solar energy returns to atmosphere. The temperature of heat carrying medium can be anywhere from 60 to 600°C, though theoretically the max could be same as Sun surface at focal point.

As to the second step, it will be constrained by Carnot efficiency that depends on the temperature of heat source and temperature drop. Usually a real heat engine, e.g. Rankine or Stirling, can be far less than Carnot's. For example, regular car engine about 20 to 30%, but its Carnot efficiency = 77% if burning at 1000°C.

To make the bi-step efficiency equivalent to PV, the heat engine must be at least 14% / 60% = 23%.

In eyes of heat engine designers, the solar thermo attainable temperature, e.g. ~150°C for flat plate type, is still regarded as low grade waste heat, even those solar concentrated systems, still less than the exhaust gas temperature of a car, therefore the required minimal efficiency 23% is still a hard challenge.

For 150°C low temperature solar heat source, its Carnot efficiency = 31% if use 20 °C underground shallow water table as heat sinker or same temperature atmosphere. But unfortunately, by any available heat engine, the most likely efficiency ~10%, hopeless to compete with PV.

Luckily, we have invented a so-called Wei-Trump engine which efficiency can be most proximalest underneath Carnot engine, than any other type of heat engine!

Descriptively, it is a special multi-cylinder heat engine with its working media phase change to associate hydraulic oil power conversion.

Is this proposal for a practice or a project?

Project

What actions do you propose?

1. Why the said heat engine is named after the majestic president Trump?

Everyone knows that an uninsulated plumbing pipe will rupture in winter, but less guys know that even a 1" thick iron pipe can not survive the tremendous icing pressure ~3000 bar with concomitant 10% volume increase!

Because Trump's face change is powerful too: easily rupture or rapture the world, so this new type heat engine reflects this historical phenomenon by the special name.

2. Everytech looks good, why the Horizon18 still calling proposals?

The technologies of PV, heat pump, solar water heater, etc, all seem mature enough, but that is just superficial good, and until now there is none convincible NZEB sample all over the world.

The major unsatisfactions: lack of economic energy storage; low efficient heat engine for low temperature; no systematic method to integrate all those sub-systems; even the PV is still too expensive.

That is why the said organization makes call.

3. Bye to the gaseous phase

To increase efficiency of heat engines, conventional liquid-gas-liquid cycle must be discarded, because gaseous phase takes too much space and renders mediocre pressure, even hardly keeps mass conservation because of emission of partial uncondensed vapor, eventually results in low energy density and low efficiency.

No more gaseous phase in new thermodynamic cycle!

Instead, we use solid-liquid-solid cycle, therefore, Phase Change Materials (PCM) are selected.

The retarded pressure of phase change can be up to sub-10000 bar, in contrast, retarded hot steam just renders humble 10 to 100 bar in regular Rankine cycle heat engine.

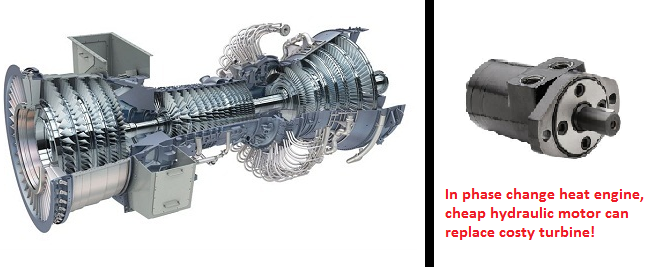

4. Bye to steam or gas turbine

Manufacture of customized utility turbine is always headache, very complicated, very costy, and no hope of standardization.

We choose standard hydraulic motor to replace turbine. There are numerous manufacturers, e.g. Parker Hannifin, Eaton, etc.

Typically, the specific power density of a steam turbine is about 0.5 kw/kg, and power density 0.3 Mw/m^3, and in contrast, for typical hydraulic motor, 5 kw/kg, 30 Mw/m^3 respectively. Therefore the enhancement is by orders of magnitude.

By conjugate drive, the working media expansion power can be easily converted to hydraulic oil power, and pressure ratio can be preset by piston area ratio of PCM side to oil side.

Hookup electricity generator to the shaft of hydraulic motor, yeah, the building can use electricity anytime.

No more turbine here now!

5. Bye to the ORC (Organic Rankine Cycle) engine

As per current market price, there is no regular family that can be affordable to a set of ORC engine, unless the likes of Bill Gates; but the Wei-Trump engine projected price could be a tiny fraction of ORC, affordable for everyone.

Because of no gaseous phase, thus there is zero emission of any PCM vapor even using a prohibited Freon; but ORC engines still risk of bad greenhouse gas emission.

No more ORC engine!

6. the engine core -- PCM to hydraulic oil pressure transformer

we use conjugate chambers to host working PCM, and both PCM soak the 2-loop heat exchanger.

When one chamber is heated due to hot fluid flow via heat exchanger, as same awhile, the conjugated aka counterpart chamber is cooled down due to cool fluid flow via heat exchanger, then the conjugate drive the common-axle.

Another pair of conjugate chambers can host hydraulic oil and share the common-axle with PCM side, so as to power external hydraulic circuit with loads.

A central logic controller must take care of the timing sequence for all relevant electromagnetic valves, which in turn switch heat exchangers to heat source or sinker.

7. Cascading multiple engine core cells to approach Carnot efficiency

Every single core cell or cylinder block can merely render low efficiency in the range of 5% to 10%, though internal phase change transition may generate hundreds to thousands times atmosphere pressure.

By cascade, the total efficiency will almost be linearly multiplied.

The rejected heat from previous core cell will feed as input to the next core cell, and so on, until the last rejected heat as small as possible & reasonable to the last aka the system heat sinker.

Usually a 8-cylinder Wei-Trump engine is very close to the Carnot efficiency. Anyway, 4-cylinder may cope with the NZEB application. Of course, all PCM melting points are different in different cylinder blocks.

8. Heat source as utility scale thermal storage

Energy storage is vital to NZEB!

To adapt our engine, there are three choices:

a. still use PCM aggregate

As a stationary application, the PCM energy density is not important. Therefore we can select cheap PCM, such as sulfur, ~$100/ton, then 6 tons can store 100+ kwh thermal, equivalent to 30 kwh electricity.

But, don't care about PCM cost for working PCM, because filling cylinders need very small quantity.

b. large amount of water in huge tank

It is the the cheapest way.

For avoiding steam generation, heating to 100°C is not recommend. But such a so-so temperature will compromise efficiency, unless in coldest winter.

c. landscape Saturated Salt Water (SSW) pond

use the Wei-Trump engine to do reverse osmosis, so as to concentrate the solution in pond, as well as generate freshwater.

use our new invented osmotic power generator by forward osmosis of freshwater to SSW.

Even with this choice, PCM can still be used for heat source buffering, so as to stabilize heat engine, but not necessary of tons mass.

for details, see this link:

http://www.linkedin.com/pulse/osmosis-energy-era-looming-yanming-wei/

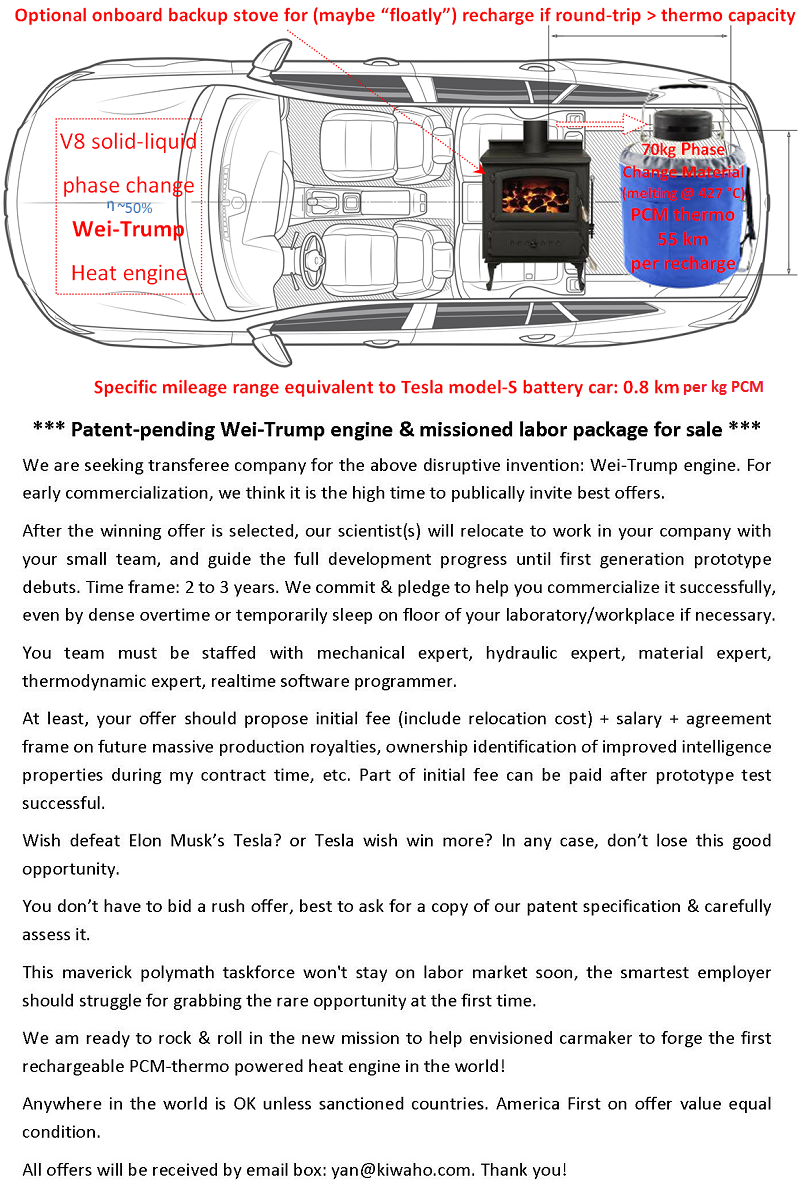

9. Outlook on automobile application

One of other most interested applications is for zero-emission cars to replace expensive lithium battery with a lithium-based storage-purposed PCM (427 °C melting point) thermo exchangeable cartridge.

The heat engine efficiency can be ~40%, better than diesel engine.

The heat of fusion of the PCM Li-thermo is 1163 kj/kg or 323 wh/kg by thermal or 160 wh/kg by mechanic. It is the highest amid all compounds around the temperature. Obviously its energy density is similar to Musk's Tesla battery.

If we don't want equivalent mileage range per recharge to Tesla, just compromise the energy density with far cheap storage-purposed PCM, e.g. KNO3, etc. good enough for those commuters with normal short mileage range 50km per recharge.

Easy integration with braking energy reclamation system, because they use same hydraulic accumulator.

Because the powertrain only transmit hydraulic oil power, so it can hookup aux 12v DC alternator to hydraulic motor, for lamps, electromagnetic valves, circulation pump, radiator fan, computer, etc. As no more starter motor, therefore, tiny lithium battery or small lead-acid battery is enough.

For details, see our article:

*** Wei- Trump engine is born! ***

http://www.linkedin.com/feed/update/urn:li:activity:6420754521185611776/

10. Outlook on LAES (Liquid Air Energy Storage) application

This will be another future application.

According to the formula of Carnot efficiency, the lower the temperature of heat source and the larger the temperature drop from source to sinker, then the higher the efficiency will be.

The omnipresent air will liquefy at cryogenic temperature -196 °C, i.e. the boiling point of liquid nitrogen. Therefore, if let the liquid air be the heat sinker and ambient normal atmosphere or the approx equivalence be the heat source, then the ideal Carnot efficiency will be circa (20 + 196)/(273 + 20) = 74%.

With the technology advancement in energy storage, the liquid air energy storage system is gradually looming prospective. Although liquefaction technology is just of old school, however the counterpart, i.e. cryogenic heat engine is still not mature.

By using a multi-cylinder i.e. multi-stage Wei-Trump, the practical efficiency shall jump up higher range: 30% to 50%.

As there are abundant choices for PCM with melting point in cryogenic range, therefore, configuring all PCM for different cylinders is relatively easy job.

11. Invaluable impressions & thoughts

After experiencing the whole innovation, we have a rude awakening:

It is the proper tech-performance trade-off that enables impossible possible!

There are many taboos in technology exploration and engineering practice. For example: stuffing solid material in hydraulic cylinder is strictly prohibited; no such thing to allow hydraulic cylinder suffering from too hot condition; small volume change expansion is discouraged for power output; etc.

However, in this great invention, all above taboos are offended. But if not, it seems there is no way to harness the retarded phase change and harvest energy from therein.

We are not to recklessly challenge taboos, instead we set a tolerance line for a trade-off remedy.

Taking one of many trade-off remedies as example: by inserting a heat-insulated spacer between the for-joint-ends of piston rods of PCM side and hydraulic oil side, then the normal working temperature of hydraulic oil can not be affected and keep same with atmosphere.

This world is never perfect, even ugly in some corners. Therefore, due trade-off has to be applied to the due time and due space for due performance, and perfectionists may often confront failure. Anyway, all our innovations just follow this philosophy.

By the way, thanks to the guidance of president Trump's book "the art of deal", without the inspiration of trade-off thereof, we would have not invented this disruptive kind of heat engine.

For other similar story, click following link:

http://www.linkedin.com/pulse/art-trade-off-invention-osmotic-hydraulic-oil-pressure-yanming-wei/

Who will take these actions?

Yanming Wei

(Yannick Weir)

Kiwaho Lab.

Will invite Eaton or Parker Hannifin

Where will these actions be taken?

ASAP

In addition, specify the country or countries where these actions will be taken.

United States

Country 2

Canada

Country 3

China

Country 4

No country selected

Country 5

No country selected

Impact/Benefits

What impact will these actions have on greenhouse gas emissions and/or adapting to climate change?

Net Zero Energy Building (NZEB) means zero emission by self-evidence

What are other key benefits?

much much more!

Costs/Challenges

What are the proposal’s projected costs?

TBD

Timeline

3 years to commercialize

About the author(s)

See linkedin homepage:

http://www.linkedin.com/in/kiwaho

Related Proposals

References

The Wei-Trump heat engine invention is freshly patent pending under the USPTO app # 16021000