Pitch

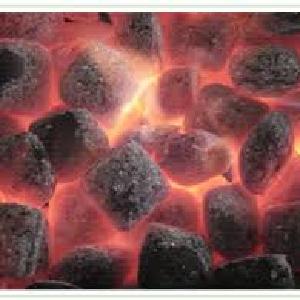

Bio briquettes produces clean and efficient energy it saves the forest and is mitigation and adaptation strategy against climate change

Description

Summary

Fuel briquettes generated by the low-pressure compaction of paper, sawdust, agricultural or yard waste, etc. currently serve as an alternative to firewood, wood pellets and charcoal. It can be produced from solid waste and from biomas. Generally, biomass can be defined as renewable organic materials that contain energy in a chemical form that can be converted to fuel. It includes the residues from agricultural operations, food processing, forest residues, municipal solid wastes and energy plantations. The use of biomass residues and wastes (for chemical and energy production) was first seriously investigated during the oil embargo of the 1970s. In recent years the use of biomass as a source of energy became of great interest world-wide because of its environmental advantages. The use of biomass for energy production, biofuels, has been increasingly proposed as a substitute for fossil fuels. Biomass can also offer an immediate solution for the reduction of the CO2 content in the atmosphere. It has three other main advantages: firstly its availability can be nearly unlimited, secondly it is locally produced and thirdly the fact that it can be used essentially without damage to the environment. In addition to its positive global effect by comparison with other sources of energy, it presents no risk of major accidents. Instead of firewood as proposed which the main contributory factor to deforestation and desertification, I recommend briquettes as a better option than drying wood to be used as fire wood.

Category of the action

Adaptation

Who will take these actions?

The key actor in this proposal is the individual who will be the final end user of the briquettes but more importantly community organizations will be trained to train others. That is train the trainer which will be done in different communities through community based organization.

Secondly, the Non governmental organization that will be responsible for conducting the training training organizing administrative and logistical arrangements for the successful take off and implementation of the set goals. There will be two trainings namely, briquette and clean energy stove production.

Thirdly, business organizations. From experience, most people turn the production of briquettes into profitable business either as sales agents and they build their production line.

Finally, the Government. The key role of the government is to give approval for the up take of this project and make laws against the indiscriminate failing of trees for fuel in this case it hardly dries to be fused so why cut it down

What are other key benefits?

This project has both environmental and socio-economic benefits some of which include:

Reduce deforestation and Fuel Wood savings; Briquettes are a good substitute for wood·

Reduce indoor pollution; they burn with a small flame and with less smoke and are clean and easy to handle·

Job creation and source of income. Jobs will be created in the production of the briquettes and the production of clean energy stove.

Carbon Emissions: The use of wood is highly regarded as a fuel because it has the potential to be environmentally neutral, in that if wood is replaced at the same rate it is used then the amount of carbon released would be negated by the new trees. Where the consumption is greater than the supply as inmost cases, there is an overall increase in carbon emissions.

Solid waste management if using waste to as the raw material for the production of briquette.

The raw material is readily available.

What are the proposal’s costs?

The project has economic cost.

Start up funds are are required to start the production of briquette and clean energy saving stoves. Specific cost involve the following:

1. Project consulting fee

2. Presses (fabrication or purchase) and supplies

3. Biomass Or Solid waste acquisition

4. Fabrication of clean energy stove

5. Travel and administrative cost

Time line

Briquettes production projects becomes self sustaining within 6 months of starting. In this case, the project involve training people to train others. This will lead to rapid replication across the country. Depending on the size and population of the country this trainings can be completed within one year and another six months for mentoring. As long as the people understand the process they become self independent and require little or no supervision. The project can then be easily phased out.

Related proposals

References

Campbell I. (1983) Biomass Catalysts and Liquid Fuel. Holt Rinehart and Winston.

Chardust (2008) Sustaining Business, Creating Jobs, Protecting thewww.chardust.com

Fuwape J.A. (1993) Charcoal and Fuel value of Agroforestry Tree Crops. Agroforestry Systems22: pp 175-179.

Republic of Kenya (2002). Study on Kenya’s Energy Supply and Policy Strategy for Households,Small-Scale Industries and Services Establishments, Final Draft Report. Ministry of Energy,Nairobi, Kenya.

Biomass Briquetting: Technology and Practices FAO Bangkok 19969.

Training on Efficient methods of Production Charcoal and Improved

CookStoves. AlbertButare 199710. Proceedings on the International

Workshop on Biomass Briquetting FAO Bangkok 199611. Revised 1996 I

PC Guidelines for National Greenhouse gas Inventories