Pitch

Jatropha curcas L. is a non-food bioenergy, a second-generation biofuel plant that provide a portion of the fuel supply.

Description

Summary

Jatrophacurcas L. belongs to the Euphorbiaceae family. Jatrophais a multipurpose plant that originated in Central America but can now be found throughout the tropics, including Africa and Asia (Openshaw 2000).

As a second-generation (non-food supply) biofuel crop, it can affordably and sustainably help to provide a portion of the current fuel supply with minimal environmental impact.

What actions do you propose?

The actions are:

- First, Jatropha cultivation awareness program in local level, regional level and national level.

- Then, small to big landholder farmers offered an opportunity to join Jatropha cultivation group.

- Formation of the Jatropha cultivation farmers groups, at least 25 person/group.

- Trained these groups 7 days about the knowledge of Jatropha plant cultivation, harvesting and its market value where they sell jatropa seed.

Jatropha cultivation :Jatropha curcus is a drought-resistant perennial, growing well in marginal/poor soil. It is easy to establish, grows relatively quickly and lives, producing seeds for 50 years.Jatropha the wonder plant produces seeds with an oil content of 37%. The oil can be combusted as fuel without being refined. It burns with clear smoke-free flame, tested successfully as fuel for simple diesel engine. The by-products are press cake a good organic fertilizer, oil contains also insecticide.

It is found to be growing in many parts of the country, rugged in nature and can survive with minimum inputs and easy to propagate.A good crop can be obtained with little effort. Depending on soil quality and rainfall, oil can be extracted from the jatropha nuts after two to five years. The annual nut yield ranges from 0.5 to 12 tons. The kernels consist of oil to about 60 percent; this can be transformed into biodiesel fuel through esterification.Then further, process for production of jet-range hydrocarbons from crude Jatropha oil using hydrogen produced in-situ from formic acid which is used for aviation.

Quality of the soil

Best in sandy well-drained soils. Can withstand very poor soils and grow in saline conditions All the actors in the Jatropha sector suggest, anyway, using organic fertilizer in order to obtain higher yield.

Irrigation

It handles dryness very well and it is possible to live almost entirely of humidity in the air where rainfall is as low as 250 mm a year. Differences are expressed in what is optimum rainfall as some readings say 600 mm and some say 800 mm whilst some areas in India report good crops with rainfall of 1380 mm. Under irrigation 1 500 mm is given.500 - 600 mm of rainfall is the limit. Below it the production depends on the local water condition in the ground

It will also stand for long periods without water - up to 2 years – and then grow again when rains occur again.

Use of fertilizer

Although Jatropha is adapted to low fertility sites and alkaline soils, better yields seem to be obtained on poor quality soils if fertilizers containing small amounts of calcium, magnesium, and Sulfur are used. Mycorrhizal associations have been observed with Jatropha and are known to aid the plant’s growth under conditions where phosphate is limiting It is recommended that 1 kg of farmyard manure/ plus 100 g of Neem waste for every seedling, with a recommendation of 2500 plants per ha this comes up to 2.5 t organic fertilizer per ha.Besides it after transplantation and the establishment of the plant fertilizer such as N, P and K should be applied. Twenty gram urea + 120 g SSP and 16 g MoP should be applied annually

Crop density

References recommend spacing for hedgerows or soil conservation is 15cm - 25cm x 15cm-25cm in one or two rows respectively and 2m x 1.5m to 3m x 3mm for plantations. Thus there will be between 4,000 to 6,700 plants per km for a single hedgerow and double that when two rows are planted.

Satisfactory planting widths are 2 x 2 m, 2.5 x 2.5 m, and 3 x 3 m. This is equivalent to crop densities of 2500, 1600 and 1111 plants/ha, respectively. Distance OF 2MX2M BE KEPT FOR COMMERCIAL CULTIVATION

Wider spacing is reported to give larger yields of fruit.

Pruning

Pruning – 1st prune

The plants need to produce side shoots for maximum sprouting and maximum flowers and seed. Between 90 and 120 Days top of all plants at 25 Cm. Cut the top off cleanly and cut top to produce 8 – 12 side branches.

Inter-cropping

Specific intolerance with other crops was not detected.

CROP YIELD

It appears very difficult to estimate unequivocally the yield of a plant that is able to grow in very different conditions.

Yield is a function of water, nutrients, heat and the age of the plant and other. Many different methods of establishment, farming and harvesting are possible. Yield can be enhanced with right balance of cost, yield, labor and finally cost per Mt

Seed production ranges from about 2 tons per hectare per year to over 12.5t/ha/year, after five years of growth. Although not clearly specified, this range in production may be attributable to low and high rainfall areas.

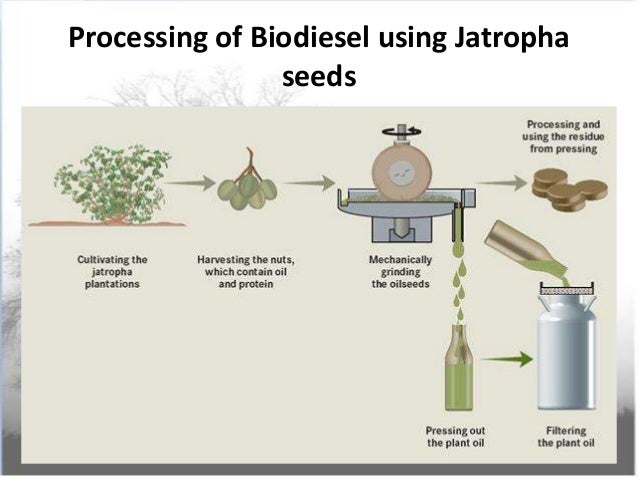

Processing of the jatropha oil into jet (aviation) fuel

When jatropha seeds are crushed, the resulting jatropha oil can be processed to produce a high-quality biofuel or biodiesel that can be used in a standard diesel car or further process for production of jet-range hydrocarbons from crude Jatropha oil using hydrogen produced in-situ from formic acid.

Oil extracting and refining equipment is available in the international market at a price of approximately $30,000. An old mustard (Brassica junceaL. Czern) expeller, which is a machine to extract oil from oil seed plants, can be modified and used for Jatrophaoil extraction. Small-scale hand-operated expellers can extract 0.26 gal (1 L) of oil per 11.0–12.1 lb (5.0–5.50 kg) of seed, while engine-driven screw presses can produce 0.26 gal (1.0 L) of oil from 4.0 lb (1.8 kg) dried seed (Henning 2002; Jongschaap et al. 2007).

There are several forms of biofuel, often manufactured using sedimentation, centrifugation, and filtration. The fats and oils are turned into esters while separating the glycerin. At the end of the process, the glycerin settles and the biofuel floats. The process through which the glycerin is separated from the biodiesel is known as transesterification. Glycerin is another by-product from Jatrophaoil processing that can add value to the crop. Transesterification is a simple chemical reaction that neutralizes the free fatty acids present in any fatty substances in Jatropha.

A chemical exchange takes place between the alkoxy groups of an ester compound by an alcohol. Usually, methanol and ethanol alcohol are used for the purpose. The reaction occurs by the presence of a catalyst, usually sodium hydroxide (NaOH) or caustic soda and potassium hydroxide (KOH), which forms fatty esters (e.g., methyl or ethyl esters), commonly known as biodiesel. It takes approximately 10% of methyl alcohol by weight of the fatty substance to start the transesterification process (Ibeto et al. 2011).

Some of the chemicals that are used in the manufacturing of biodiesels are ethanol or methanol that bring into use methyl esters. Methanol is derived from fossil fuels, and ethanol is derived from plants. In the transesterification stage, the by-product is glycerol, which is approximately 10% of the raw oil by weight. Glycerol yield can be less than 10% of the raw oil, and a greater conversion to glycerol means greater revenue, assuming that the price of the glycerol remains constant. Revenues generated from coproducts like glycerol can reduce the net marginal cost of biodiesel production (Brittaine and Lutaladio 2010).

Estimates of Jatropha seed yield vary widely, due to a lack of research data, the genetic diversity of the crop, the range of environments in which it is grown, and Jatropha's perennial life cycle. Seed yields under cultivation can range from 1,500 to 2,000 kilograms per hectare, corresponding to extractable oil yields of 540 to 680 litres per hectare (58 to 73 US gallons per acre). In 2009 Time magazine cited the potential for as much as 1,600 gallons of diesel fuel per acre per year.The plant may yield more than four times as much fuel per hectare as soybean, and more than ten times that of maize (corn), but at the same time it requires five times as much water per unit of energy produced as does corn. A hectare of jatropha has been claimed to produce 1,892 litres of fuel.

Process for production of jet-range hydrocarbons from crude Jatropha oil using hydrogen produced in-situ from formic acid

A team at the Korea Institute of Energy Research has developed a catalytic process for the production of jet-range oxygen-free hydrocarbons from crude Jatropha oil, using hydrogen produced in-situ from formic acid.

In a fixed bed reaction using a mixture of crude Jatropha oil and formic acid, normal hydrocarbon in the range of C10–C18 (mostly C15 and C17) was the main product—about 97% in the liquid product—and the degree of deoxygenation was about 99.5%.

Generally, bio-jet fuel is produced from non-edible oils via previously mentioned commercial processes, where oils are hydro- deoxygenated and hydro-isomerized/cracked with hydrotreating catalysts and then distillated in sequence. However, a great amount of hydrogen is required to remove the oxygen in the molecules of oils (300–420 m3 of H2/m3 of vegetable oil). For minimization of hydrogen consumption, decarboxylation reaction of oils has been studied to take oxygen out of the oil molecules as CO2 gas, instead of hydro-deoxygenation. Recently, the direct formic acid fuel cell has been developed for portable power applications, where formic acid is a promising alternative fuel because it can produce hydrogen at relatively low temperatures over Pd/C catalyst (HCOOH → CO2 + H2). Therefore, in the present study, formic acid was applied for catalytic deoxygenation reaction, as not only a co-reactant but also a hydrogen donor. We conducted the catalytic decarboxylation reaction of crude Jatropha oil (CJO) over Pd/C catalyst to produce oxy-free hydrocarbons, assisted with hydrogen in-situ produced from formic acid solution (30%).

Catalytic deoxygenation for the production of n-paraffin from triglyceride: (a) decarboxylation reaction from triglyceride and (b) decarboxylation reaction in assistance with hydrogen in-situ produced from a hydrogen donor (glycerol).

http://www.greencarcongress.com/2016/02/20160216-cjo.html

—Hwang et al.

The major debate of growing biofuel crops worldwide is food vs fuel issue which has led to decision of growing non-food source bio-energy crop in degraded land.

If the Jatropha plantation is carried out only in marginal land without any kind of competition with the food crops then it can reduce energy insecurity of the country without affecting food security, rather promotes rural development.

(Pradhan, n.d) carried out a research to examine the case of biofuel in Nepal and to provide important recommendations on sustainable production of biofuel without affecting food security of country. This study shows that if Jatropha cultivation is carried out in a sustainable way without diverting land, food, water, and labor, then it secures energy access, provides employment generation, can reduce GHG emission and also reduce indoor pollution thereby improving the health condition.

For production of the huge amount of the jatropha oil motivation of the farmers to grows jatropha own their degraded land only and proper credit mechanism needs to be developed by the governments to help small farmers to cultivate and sell crop profitably.

Economic feasibility

The economic feasibility (studied in India) of prepared biodiesel was calculated by calculating the various economics of jatropha plantation, jatropha oil extraction, jatropha ethyl ester production. The cost of oil per kg and JEE production cost per liter was found to be Rs. 25.34 ($0.40 and 28.64 ($0.45), respectively.

www.ijat-aatsea.com/pdf/v8_n2_12.../21_IJAT%202012_8_2__Samodini%20S.pdf

Jatropha biodiesel production in the biodiesel processor were developed and started with oil of Jatropha. The cost of production for the processor was around Rs. 5000 ($500) and plant age was considered approximately 10 years. The cost of JEE was estimated as Rs. 28.64 ($0.45) by considering seeds and Jatropha oil cost of Rs. 6/kg ($0.096) and Rs. 26/kg (0.41), respectively. Biodiesel production was found to be affordable and comparable to the existing diesel prices.

Who will take these actions?

The key actors are:

Governments, Industries, Private sectors, Airlines and Farmers.

Where will these actions be taken?

Worldwide

How much will emissions be reduced or sequestered vs. business as usual levels?

As a perennial shrub, Jatrophacan sequester carbon (C), a full-grown tree absorbs around 7.9 kg of CO2 every year (PSO 2010). If the plant density is 1,012 plants.acre-1 (2,500 plants.ha-1), it is possible to acquire an 8.7 t.acre-1 (18.1 t.ha-1) of greenhouse gas sequestration per year.

Jatrophaproduces renewable energy in the form of biodiesel, which emits 80% less CO2 and 100% less SO2 than fossil diesel (Tiwari et al. 2007).

What are other key benefits?

The key benefits are:

- Jatropha easy to cultivate, cost effective, can grow on all the climatic conditions and soils.

- The percentage of yield is high and the extraction of oil is also maximum.

- Jatropha provides higher rate of output than any other crops.

- Drought resistant plant.

- Ability to grow well on poor and infertility soil, in marginal areas and can withstand any type of climate.

- Needs only little amount water and maintenance.

- The plant can be harvested for about 50 years.

- High oil content

- Small development period

- Grow in low and high rainfall areas

- Does not require any special maintenance

- Can be harvested in non-rainy season

- Multi products are developed using a single jatropha plant. The products include bio-diesel, soap, mosquito repellent, and organic fertilizer.

- Tests conducted by the EPA have shown that the hydrocarbon emissions of Jatropha biodiesel are roughly half that of fossil diesel, leading to a reduced carbon footprint.

What are the proposal’s costs?

Proposal cost calculated in context of Nepal

ASSUMPTIONS FOR COST/BENEFIT ANALYSIS

- Though Jatropha starts yielding from very first year, we have taken no yield for 1st and 2nd year just to ensure proper pruning and development of the plant

- Crop density with 2mx2m pattern shall be 2500 plants per ha

- Seeds tonnage per ha has been taken 0,0, 2.5, 5.0, 6.25, 9.6 for 1, 2, 3, 4, 5, and 6th year respectively

- Intercropping has been presumed for 30% of plantation area

- CDM calculation has been taken as minimum for +1000 ha plantation

- Sale price of seeds has been taken on lowest side

- Rate of interest has been taken as 9% per annum for 5 years

1 hatare jatropha - plantation cost

Crop cultivation cost $650/-

Crop yield $1050/-

Crop harvest cost $ 160/-

Crop care cost $154/-

Revenu $736(in 1 year)

Program Cost

Jatropha cultivation awareness program US$6500.00/-

Formation of the Jatropha cultivation farmers each group- US$100.00/-

Each group(25 person) 7days training cost = US$2670.00/-

Machine purchase for Oil extracting and refining price of approximately $30,000./-

Other cost $5000.00/-

Total cost (Plantation cost+Program cost)= $47020/-

Time line

- Awarenee program and group formation within 3 month.

- Field preparation 3-4 month

- Jatropha cultivation 4-5 month

- Starts yielding from 9-12 months

- Best yields are obtained only after 2–3 years

- Biodiesel production 2 -50 years. Jatropha is a perennial crop and a single tree can continue to produce fruit for up to 50 years.

Related proposals

References

Brittaine, R., and N. Lutaladio. 2010. Jatropha: A Smallholder Bioenergy Crop – The Potential for Pro-Poor Development. Rome, Italy: Food and Agriculture Organization of the United Nations. Accessed August 25, 2011.http://www.fao.org/docrep/012/i1219e/i1219e.pdf.

Henning, R. 2002. "Using the Indigenous Knowledge of Jatropha: The Use of JatrophacurcasL. Oil as Raw Material and Fuel."IK Notes 47 (August): 1–4. Accessed August 25, 2011.http://www.worldbank.org/afr/ik/iknt47.pdf.

http://agriculturecornerblog.blogspot.com/2012/05/i-n-global-scenario-where-world-is.html

http://agrifarming.in/jatropha-cultivation

http://e360.yale.edu/feature/for_greening_aviation__are_biofuels_the_right_stuff/2160/

http://large.stanford.edu/courses/2010/ph240/glover2/

http://large.stanford.edu/courses/2010/ph240/glover2/

http://www.altenergy.org/renewables/jatropha-biodiesel.html

http://www.aumkiipure.com/advantages-of-jatropha.html

http://www.ecofys.com/files/files/ecofys-2013-biofuels-for-aviation.pdf

http://www.greencarcongress.com/2016/02/20160216-cjo.html

http://www.jatrophabiodiesel.org/aboutJatrophaPlant.php?_divid=menu1

http://www.jatrophabiodiesel.org/drRKHeaning.php

http://www.jatrophabiodiesel.org/farming.php

http://www.jatrophabiodiesel.org/making-biodiesel.php

http://www.jatropha-bio-fuel.com/Pitch

http://www.sciencedirect.com/science/article/pii/S1876107013000606

https://edis.ifas.ufl.edu/hs1193

https://en.wikipedia.org/wiki/Jatropha_curcas#Cultivation

https://en.wikipedia.org/wiki/Jatropha_curcas#Jet_fuel

Ibeto, C. N., A. U. Ofoefule, and H. C. Ezugwu. 2011. "Analytical Methods for Quality Assessment of Biodiesel from Animal and Vegetable Oils." Trends in Applied Sciences Research 6: 537–553.

Openshaw, K. 2000. "A Review of JatrophacurcasL.: An Oil Plant of Unfulfilled Promise." Biomass Bioenergy 19: 1–15..) with High Free Fatty Acid: An Optimized Process." Biomass Bioenergy 31: 569–575.

Tiwari, A. K.; Kumar, A. & Raheman, H. (2007). Biodiesel Production from Jatropha Oil (Jatropha curcas) with High Free Fatty Acids: An Optimized Process. Biomass & Bioenergy, 31, pp 569-575.

www.aepc.gov.np/old/images/pdf/potential%20and%20prospective.pdf

www.sabreairlinesolutions.com/pdfs/BioFuels.pdf